The Process Steps

Raw Material Handling

Bales of fiber are placed on a conveyor which transports them to the Stock Prep process.

Stock Cleaning

The stock travels to a set of coarse screens & cleaners that remove heavyweight debris such as plastics, dirt and metal.

Stock Screening

Screens are used to remove finer dirt and debris.

Stock Refining

Stock flows to a refiner system where sheet properties such as tensile and porosity are developed. Refiners mechanically hydrate/fibrillate the fibers.

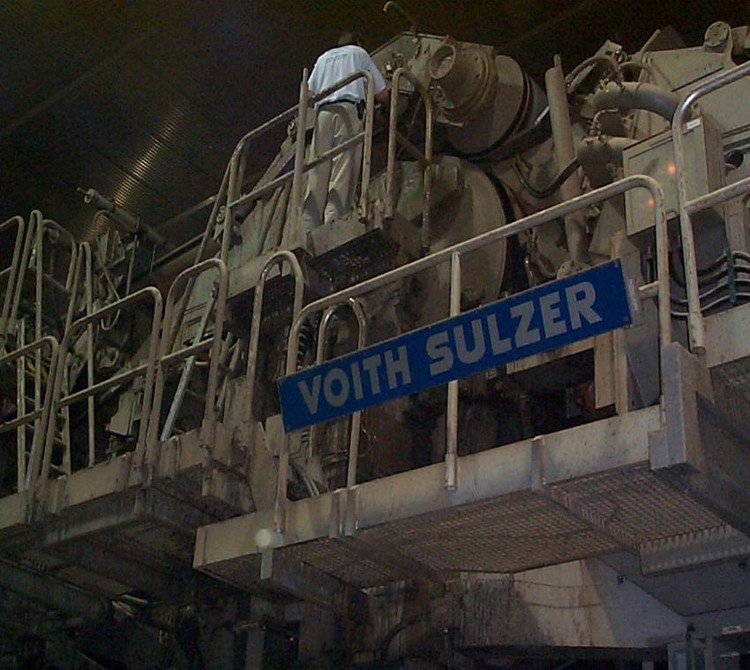

Sheet Forming

The stock travels to the Headbox/Wet End of the Paper Machine. This is where the paper sheet actually begins to form.

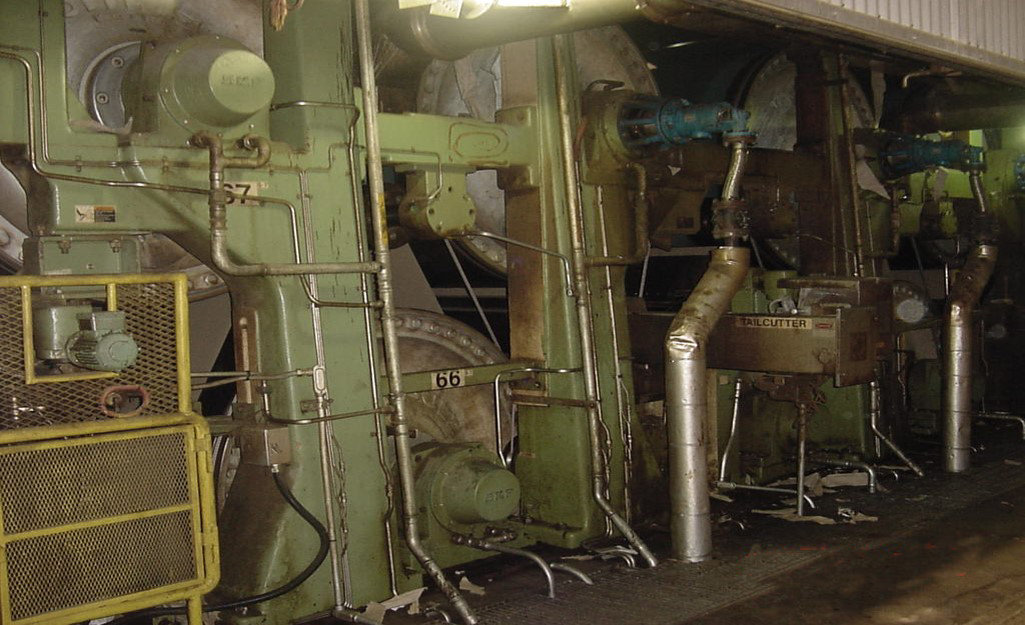

Sheet Drying

After the sheet exits the press section it enters a drying section where steam is used in 67 cans, with temperatures ranging from 100° to 350° F, to dry the sheet to its final moisture of 6%.

The Winder

The winder cuts the parent roll to various widths and diameters.

Finished Rolls

The Winder uses slitters/knives to cut the parent reel to the finished width.

Finished Roll Packaging

The roll is wrapped and labeled with information such as weights, dimensions, tracking numbers, etc.

The Warehouse

The roll is transported to the finished goods warehouse and stored prior to shipment.

Shipments

The rolls are loaded onto flatbed trucks, vans, or railcars as customer orders are placed.

Fulfilment & Transport

- Service customers via rail, flatbed, van and intermodal

- Operate 24 hours per day, 365 days per year

- Create various load patterns to accommodate customer equipment

- Control delivered costs by maximizing load weights and/or MSF

- Maximize rail loading at 30 – 31 rolls (87-93 tons)

- Maximize flatbed loading at 8 rolls (24 tons)

- Maximize van/intermodal loading at 7 rolls (21 tons)

- Operate a pre-load service and drop yard that eliminates carrier wait time or need to tarp

- Utilize external warehousing to support customers’ JIT practices and provide reduced delivered paper cost

Do You Need Any Help?

Do You Need Any Help?