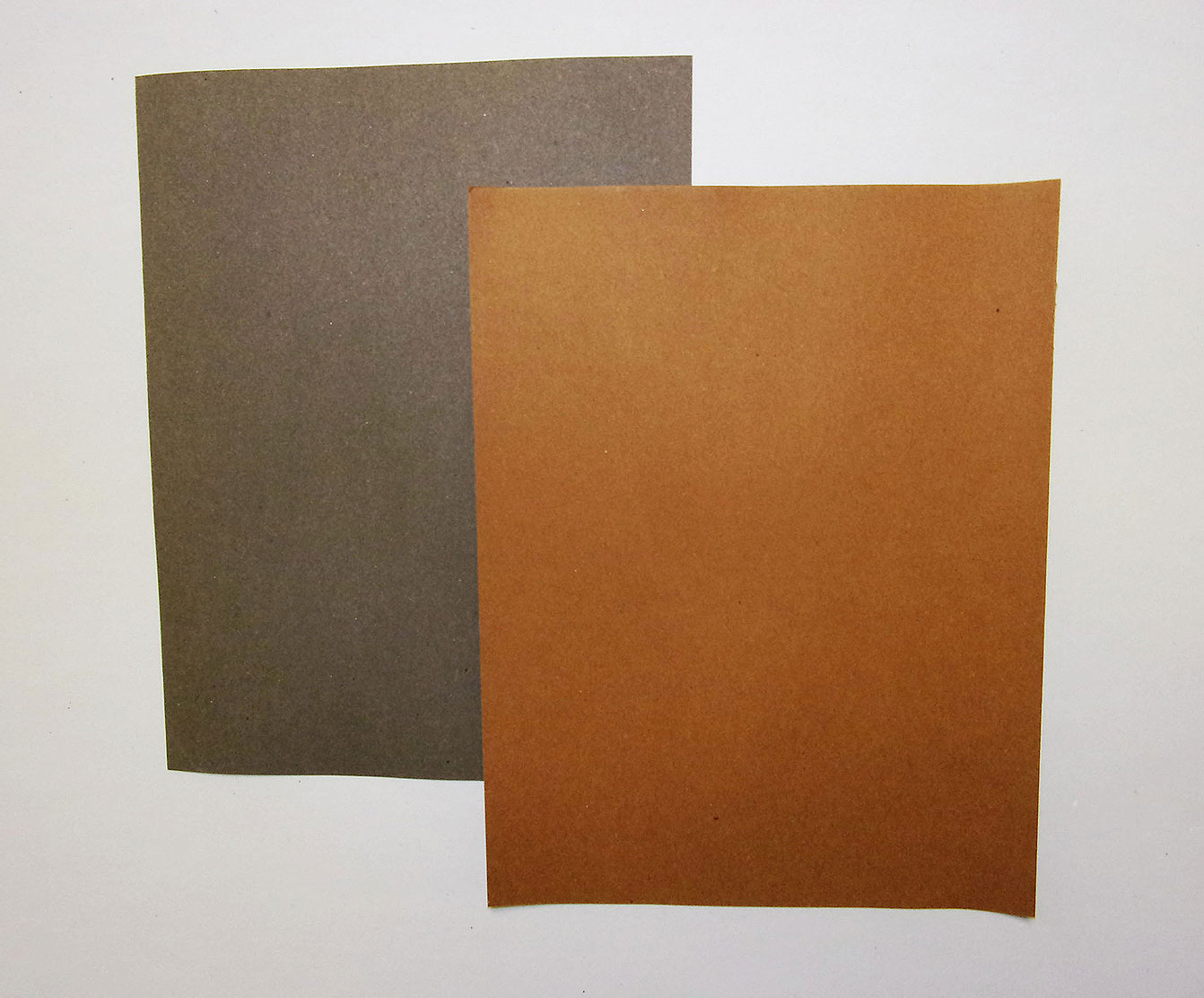

Sheathing Face & Back

Sheathing paper is available for both face and back applications to produce Sheathing Board which is used to form a surface onto which other material can be applied. It is available in basis weights from 42# to 54# per thousand square feet (MSF). This product was developed to enable builders to use a lighter weight board (1/2 inch versus 5/8) and have the same sag resistant properties. It is generally produced in a golden brown or black color to distinguish it from standard wallboard.

All Republic Paperboard products can be customized to fit your needs! Contact our sales team and we’ll be happy to work with you to create the product that meets your exact specifications. Contact Us Today

GENERAL SPECIFICATIONS

| Critical Properties | UOM | Min | Target | Max | Test Method | Method Comments |

|---|---|---|---|---|---|---|

| Basis Weight | lbs/msf | -2.0 | as ordered | +2.0 | ABB Scanner | |

| Moisture | weight % | 7.5 | 9.00 | 10.5 | ABB Scanner | |

| Porosity | sec/100cc | Grade Dependent | Autoline | Gurley; 5-min 300°F cure | ||

| Face Cobb | g/100cm^2 | 0.30 | 0.80 | 1.50 | T-441 | 10-min 250°F cure; 3-min 120°F water |

| Bond Cobb | g/100cm^2 | 0.50 | 0.70 | 1.2 | T-441 | 10-min 250°F cure; 3-min 120°F water |

| ZDT | psi | -20 | BW dependent* | ----- | T-541 | Uncured |

| MD Tensile | lbs/in | -10 | BW dependent* | ----- | Autoline | 5-min 300°F cure |

| CD Tensile | lbs/in | -4 | BW dependent* | ----- | Autoline | 5-min 300°F cure |

| Smoothness Sheffield | SU | 350 | Autoline | 5-min 300°F cure | ||

| Coefficient of Friction | degrees | Grade Dependent | T-815 | Uncured; test 3x, record 3rd value | ||

| Expansion 180 sec | % | -0.30 | BW dependent* | +.30 | CD Wet | Uncured; 10” strip |

*BW Dependent Targets:

| BW | 38/42 | 48 | 54 |

|---|---|---|---|

| MD Tensile | 83 | 90 | 95 |

| CD Tensile | 28 | 32 | 35 |

| ZDT | 80 | 75 | 73 |

| Expansion | 1.15 | 1.0 | 0.80 |

Additional Requirements:

Surface Quality – Paper shall be uniform in appearance and formation. Examples of defects include, but are not limited to: orange peel, discoloration, tiger striping, streaking, spotting (dirty face), fuzzing, fish hooks, cockles, excessive wire, felt, press roll, or other marking.

Flatness – Paper shall lie flat - free of cockles, edge warp, curling, and grooves.

Holes – Paper shall be reasonably free from holes (no repetitive MD holes). Holes smaller than 3" may be patched (no more than 2 per roll).

Roll Quality – Rolls shall be tightly wound. No telescoping. No wrinkles. No crushed or damaged cores. Splices shall be clearly marked. No splices 1" from the top. Core diameter: 4".

Physical Damage – Paper shall be free from physical defects including, but not limited to tears, edge nicks, excess moisture.

Packaging – Rolls shall be packaged to prevent damage during transport (ex: plastic wrapped). Rolls shall be marked to indicate bond side and labeled with roll number, basis weight, MD & CD tensile strength, top & bond cobb, and porosity.

Do You Need Any Help?

Do You Need Any Help?